Inventory Management is perhaps one of the most important functions of any business. Be it the raw materials, the unfinished goods, or the completed products, it is the inventory that determines the efficiency and customer satisfaction of the business. When BBA students first learn about the objective of inventory management or the types of inventory management systems, they probably think about it as being very theoretical and conceptual. However, these ideas very much affect the operational efficiency of the business.

What is inventory management?

Inventory management is when a company figures out how much inventory to keep and manage how to plan and utilize their stock to keep their operations running smoothly and profitably. It decides how much to order, when to reorder, and how much stock to keep. A company runs smoothly when their inventory system finds the right balance to avoid overspending while keeping their stock levels sufficient to meet their needs.

Let’s explore the primary goals of inventory management through the lens of real-world scenarios and easy to understand business examples.

Objectives of Inventory Management

Guaranteeing Seamless Production and Sales

One of the key Objective of inventory management is ensuring that operational processes run smoothly and without disruption. Consider a bag production unit, for instance, preparing school bags for an oncoming school calendar. If process fabric rolls or zippers are not obtained on time, production comes to a crushing halt. Workers sit without anything to do, deadlines are missed, and profits are lost.

With sound planning of the inventory, businesses achieve the balance for all three categories of inventory – raw and processed, and finished in order to ensure that customers get their products on time and that production is never stalled due to a deficiency.

Keeping Inventory at Desirable Range

‘Desirable’ translates to not having too much and also not having too little.Having too much inventory can create problems too.

- Cash flow can be effected.

- You may need more warehouse space.

- Damaged and spoiled inventory can happen.

However, having too little inventory can create problems too, such as loss of sale opportunities and poor customer experience.

The balance of inventory/sales is maintained by demand forecasting, historic sales data and lead time analysis. If businesses understand their data well, they can stock effectively.

Cost Management (Ordering, Holding, and Shortage Cost).

There are several types of costs associated with inventory. Cost of ordering is related to sending and receiving orders. Cost of holding includes rent, storage electricity and insurance. Shortage costs are incurred when stock-out situations lead to missed sales.

The goal of effective inventory management is to not just keep inventory, but manage it in a way to minimize these costs. If a business more effectively manages their ordering patterns, they can save thousands.

Customer Satisfaction

In the business environment today, customers can and will choose to work with businesses that are able to offer the right inventory and service it in a timely manner. When businesses manage their inventory well, employees and customers never experience the “out of stock” problem. This improves customer satisfaction.

Every day we use, wear, or buy electronics, and consumers appreciate customer service and an easy shopping experience. Companies that are good at managing their stock give their customers a better product at an easier price.

Reducing Waste and Keeping Items Useful

Many companies sell products that have a shelf life. Food and drinks, cosmetics, tech, and clothing lose worth and usefulness if they are kept for too long.

An effective inventory system means that:

Stock is cycled correctly

Items are kept from spoiling

Loss from damages or theft are kept low

This means that you make money and your warehouse functions better.

Helping Companies Organize their Money Better

How much money you have invested in stock changes your working capital, and inventory has a big effect on working capital. When you have precise inventory values, you can more easily manage your finances, deal with budgeting, stock purchasing, and planned spending.

When companies have precise values of their inventory, they are better able to:

Identify their best selling and worst selling products

Distribute their finances in a better more efficient manner

Create efficient production schedules

Avoid debt

This means that good inventory management can help a company achieve better financial stability.

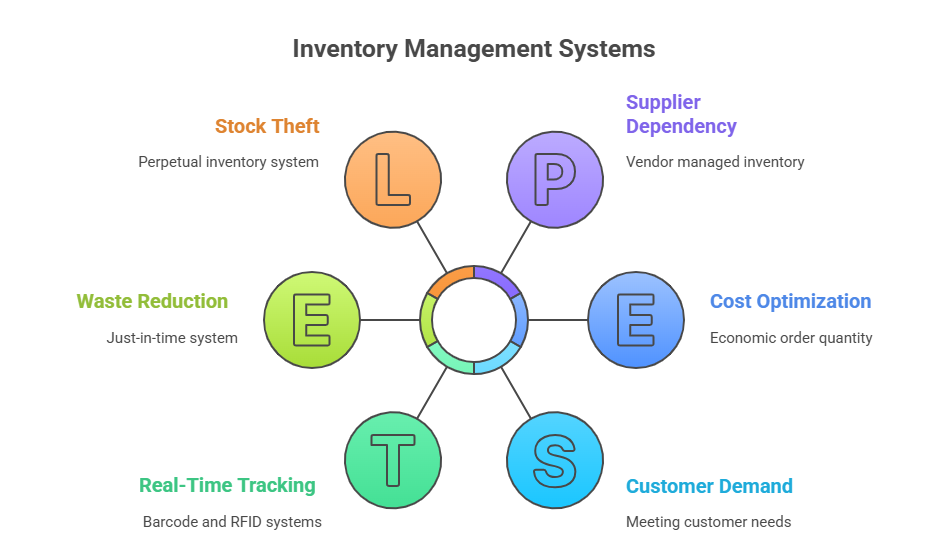

Different Types of Inventory Management Systems

We know the goals of an inventory system, and we can discuss different types of inventory management systems, focusing on how inventory is tracked, maintained, logged, and restocked. Here are some of the main systems in use today.

Perpetual Systems

Real time records of stock are kept with this inventory system. When items are received, sold, or issued, records of stock are automatically adjusted. To help manage this system, many businesses use bar code scanners or RFID tags.

For businesses that sell a large amount of products, this system works especially well. Management can get accurate, real-time stock reports at any time of day. The perpetual system is able to greatly minimize the chances of stock theft or stock being sold out due to the systems accuracy.

Periodic Systems

Inventory is not updated on a daily basis with this system, making this a simpler system than with perpetual. Physical counts of inventory are performed at regular time intervals instead.

This approach is often seen with small retail shops or boutiques. This is because the amount of transactions on a daily basis are often very limited and therefore continuous updating is not necessary. The drawback is that overstocking or stock steaming can happen, especially if a manager is being careless.

Systems Just-In-Time (JIT)

In this system, stock is ordered only when it is necessary. The main purpose of this system is to keep very little stock or to not keep stock at all in order to lower costs associated with holding stock.

Consider a small workshop business with a limited storage area. To make things easier, they usually try to work with their suppliers to receive raw materials only when there are production runs scheduled. This arrangement saves the business money, but they lose money when suppliers send materials late. If suppliers are late sending materials, the production schedule will get disrupted, costing the business a lot of money.

ABC Analysis System

ABC Analysis classifies inventory into 3 groups based on their importance.

A Inventory – most important and most expensive, least amount on hand {so a business must carefully and actively manage what they have on hand}

B inventory – moderate importance and value.

C inventory – least important but the highest volume.

A Inventory and C inventory are the most important for a business to manage. This helps ensure they prioritize their attention.

Economic Order Quantity System

EOQ helps businesses to have the lowest respiting ordering and holding costs. This EOQ system helps a business evaluate their costs in the most rational way.

For example, EOQ lets a business decide the optimal amount to order to meet the needs of their customers and to decide if they should place an order only when they don’t have inventory or to place several orders at defined intervals.

For example, if the business has an expected monthly demand from customers that is known and consistent, there will be a point at which it is most economical {in the sense of costs} for the business to order inventory a limited number of times in that month in order to minimize their costs.6. Vendor Managed Inventory (VMI)

With VMI, the suppliers takes on the responsibilities of organizing and restocking a business’s stock. Businesses do not have to track their stock on a daily basis, the vendor takes the business’s stock levels into account and ensures the business has enough inventory on hand.

This method works nicely if there is an established level of trust with the supplier. This method also alleviates some of the responsibilities placed on purchasing.

Barcode & RFID Systems

Modern Inventory Systems depend on technology. With barcodes, employees can quickly scan items and with RF ID tags, stock levels can be tracked without the need to be in close proximity.

There is a lot of time to be saved in stock taking and there is a lot of visibility into the stock in real-time. These systems are widely used in warehouses and shops.

Benefits of Understanding These Systems

There is a lot of value in understanding inventory. Understanding the systems of inventory management will help ssssetnn in increasing their capacity to make valuable financial and operational decisions.

Inventory is a key component of e-commerce, retail, and logistics. These concepts and systems are important to have if there is a need to be in the position to think critically and at a high level.

FAQs

What are the main objectives of inventory management?

The primary objectives include maintaining smooth production, avoiding stock-outs, reducing holding and ordering costs, minimizing wastage, and supporting better financial planning.

Which are the commonly used types of inventory management systems?

The major systems include perpetual, periodic, JIT, ABC analysis, EOQ, VMI, and RFID/barcode-based systems.

Which system is best for small businesses?

Small businesses often prefer periodic systems because they are simple and affordable. However, with growth, shifting to a perpetual or barcode-based system brings accuracy.

Why is JIT considered risky?

Because even a small delay from the supplier can stop production. This system requires strong coordination and reliable suppliers.

👨💼 Author: BBAProject Editorial Team

✍️ The BBAProject Editorial Team comprises business graduates and educators dedicated to creating practical, syllabus-based learning resources for BBA students.

⚠️ Please Note: Articles published on BBAProject.in are well-researched and regularly updated. However, students are advised to verify data, statistics, or references before using them for academic submissions.